Bellows Type

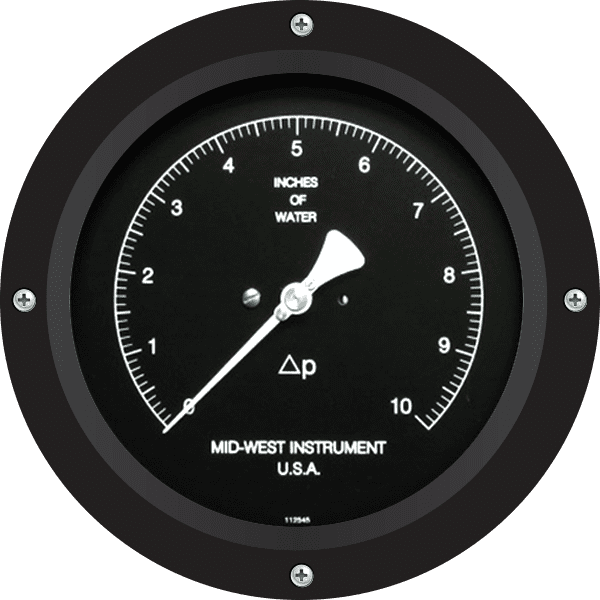

Model 105

Mid-West Instrument Model 105 Bellows ΔP Gauge – ± 1/2% or ± 1% Full Scale Accuracy. System pressure is applied to the internal volume of a bellows and mechanical linkage assembly. As pressure changes, the bellows and linkage assembly move to cause an electrical signal to be produced or to cause a gauge pointer to move.

Model 106

Mid-West® Instrument Model 106 Bellows ΔP Gauge – ± 1/2% or ± 1% Full Scale Accuracy. System pressure is applied to the internal volume of a bellows and mechanical linkage assembly. As pressure changes, the bellows and linkage assembly move to cause an electrical signal to be produced or to cause a gauge pointer to move.

Model 115

Mid-West® Instrument Model 115 Tank Level ΔP Gauge – ± 1% Full Scale Accuracy. System pressure is applied to the internal volume of a bellows and mechanical linkage assembly. As pressure changes, the bellows and linkage assembly is mechanically coupled to the gauge indicator pointer.

Model 116

Mid-West® Instrument Model 116 Tank Level ΔP Gauge – ± 1% Full Scale Accuracy. System pressure is applied to the internal volume of a bellows and mechanical linkage assembly. As pressure changes, the bellows and linkage assembly is mechanically coupled to the gauge indicator pointer. If equipped with a micro-switch, a cam mechanically linked to the bellows, rotates and triggers the micro-switch.

Bourdon Type

Model 109

Mid-West® Instrument Model 109 Bourdon Tube ΔP Gauge – ± 1/2% or ± 1% Full Scale Accuracy. System pressure is applied to the inside of a slightly flattened arc- shaped tube. As pressure increases, the tube tends to restore to its original round cross-section. This change in cross-section causes the tube to straighten.

Piston Type

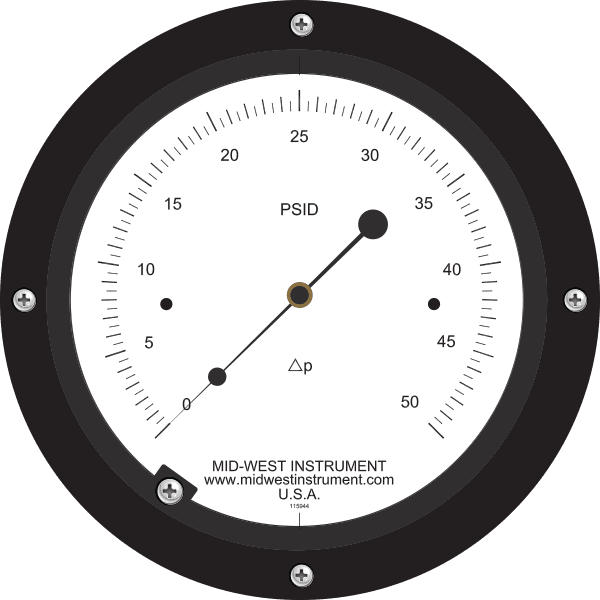

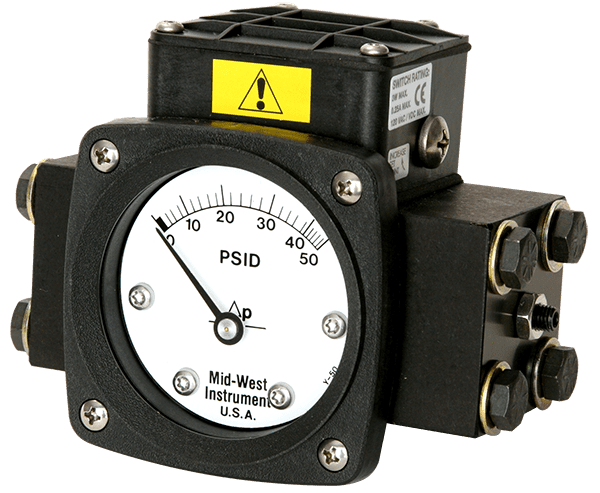

Model 120

Model 120 – The Mid-West Instrument piston type gauge is our most versatile and customizable differential pressure gauge to fit your most demanding requirements. Available with multiple switch options including Hazardous location options. With a Full scale accuracy of ±3/2/3% combined with Differential pressure dial scales of 0-5 PSID to 0-110 PSID this rugged design is ready to do the job.

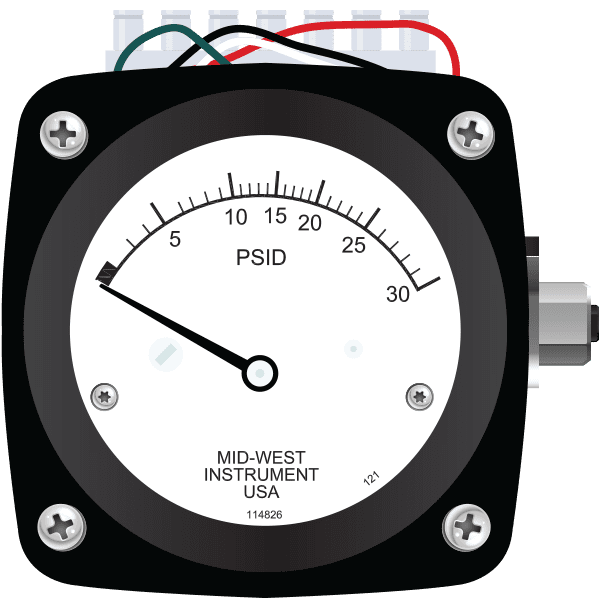

Model 121

Model 121 –Is provided with a terminal strip interface to aid in ease of electrical installation of your switch or transmitter . The Model 121 also has the option to add a 4-20 mA transmitter for applications that require constant remote monitoring. With a Full scale accuracy of ±3/2/3% combined with Differential pressure dial scales of 0-5 PSID to 0-100 PSID, the Model 121 is an accurate and versatile differential pressure switch for your most demanding DP requirements.

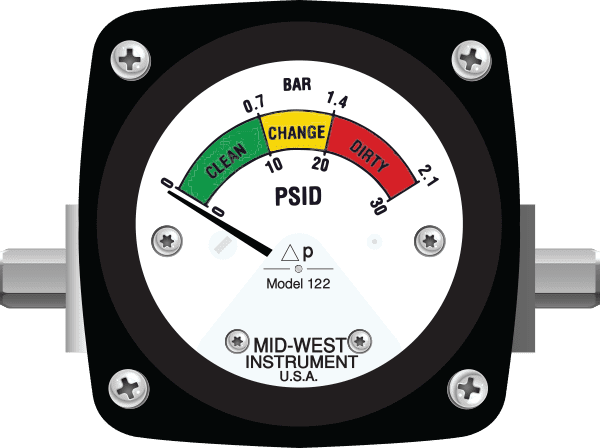

Model 122

Model 122 – Our most affordable entry level piston gauge with a Full scale accuracy of ±5% combined with Differential pressure dial scales of 0-5 PSID to 0-110 PSID. Model 122 is available with clamp on electrical switch options. There are fewer options available compared to the Model 120, but the Model 122 has a lower price point while still delivering exceptional performance.

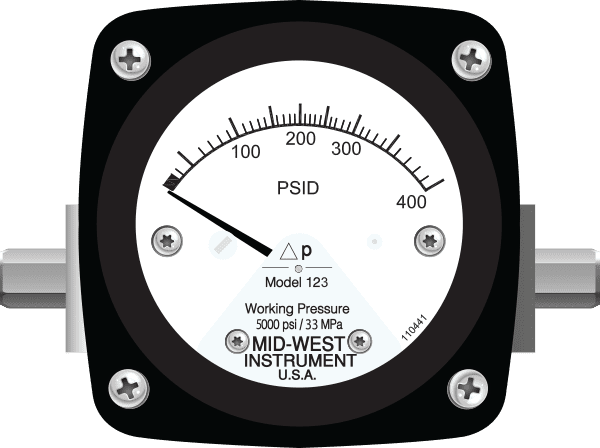

Model 123

Model 123 – Used on systems with high differential pressure requirements, the Model 123 offers a differential pressure ranges from 0-150 PSID to 0-400 PSID. The Model 123 offers safe working pressures up to 4,000 PSI, With a Full scale accuracy of ±3/2/3%. Model 123 is a versatile, accurate differential pressure gauge for your high differential pressure range most demanding DP requirements.

Model 124

Model 124 – Used on systems with working pressure up to 10,000 PSI. All Switch options on the model 124 are of the terminal strip type which aid in the ease of electrical installation. With a Full scale accuracy of ±3/2/3% combined with differential pressure dial scales from 0-5 PSID to 0-400 PSID, the Model 124 offers a versatile, accurate differential pressure gauge for your high working pressure most demanding DP requirements.

Model 220

Mid-West Instrument 220 indicating / non-indicating differential pressure transmitter is a 2 wire loop powered microprocessor based 4-20 mA transmitter. The magnetic angle sensor & electronics senses the angle (relative to the transmitter sensor) of the magnet which moves linearly in the bore. Each transmitter is individually calibrated to the gauge using an 11 point calibration linearization technique.

Diaphragm Type

Model 114

± 2% Full Scale Accuracy Decreasing. With the Diaphragm type tank level gauge the high and low-pressure ports are completely isolated from each other. There is no bypass and therefore they can be used for air, gas and liquids. They also come in a variety of dial scales allowing for very sensitive measurements.

Model 130

Model 130 – Mid-West Instrument convoluted diaphragm type gauge is our most versatile and customizable differential pressure gauge to fit your most demanding requirements. Available with multiple switch options including Hazardous location options. With a Full scale accuracies of ±5% (0-5” to 0-9.9” H2O) and ±3/2/3% (0-10” to 0-15 PSID /400” H2O) this rugged design is ready to do the job.

Model 140

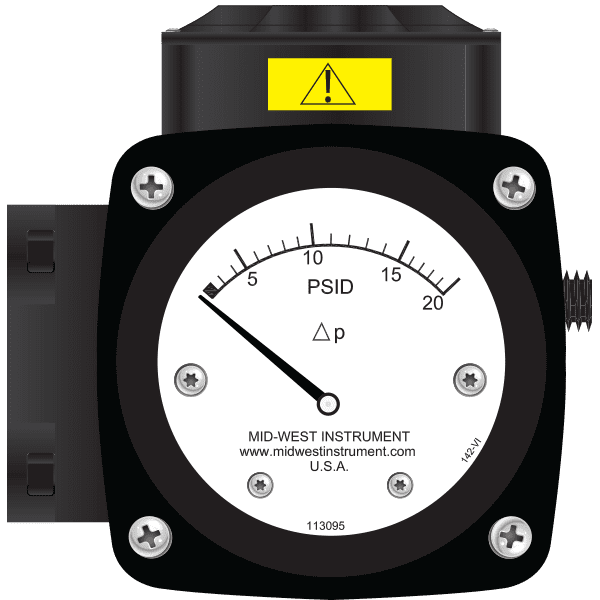

Model 140 – Mid-West Instrument convoluted diaphragm type gauge provides a terminal strip interface to aid in ease of electrical installation of your switch or transmitter. The Model 140 also has the option to add a 4-20 mA transmitter for applications that require constant monitoring. Available with multiple switch options including Hazardous location options. Full scale accuracies of ±5%(0-50” H2O to 399” H2O) and ±3/2/3% (0-15 PSID to 0-100 PSID) are available.

Model 142

Model 142 – Mid-West Instrument convoluted diaphragm type gauge provides a terminal strip interface to aid in ease of electrical installation of your switch or transmitter. The Model 142 also has the option to add a 4-20 mA transmitter for applications that require constant monitoring. Available with multiple switch options including Hazardous location Class I Div 2 options. Full scale accuracies of ±3/2/3% (0-20” H2O to 0-25 PSID) are available.

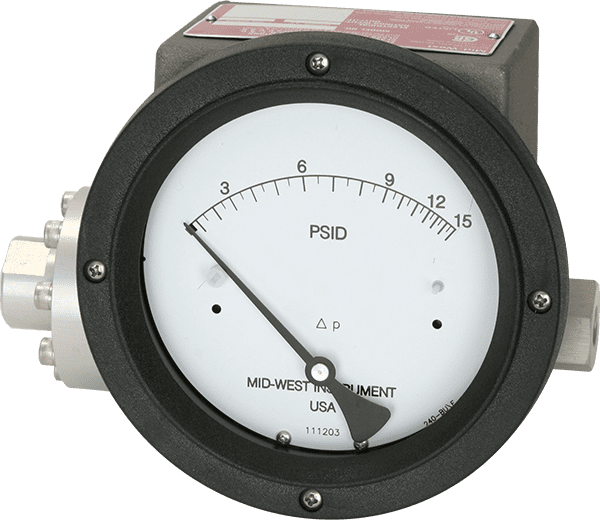

Model 240

Mid-West Instrument 240 indicating / non-indicating differential pressure transmitter is a 2 wire loop powered microprocessor based 4-20 mA transmitter. The magnetic angle sensor & electronics senses the angle (relative to the transmitter sensor) of the magnet which moves linearly in the bore. Each transmitter is individually calibrated to the gauge using an 11 point calibration linearization technique.

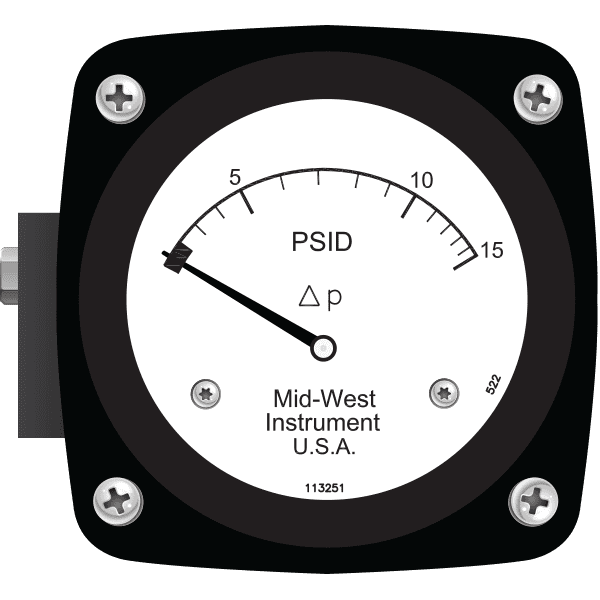

Model 522

Model 522 – Mid-West Instrument rolling diaphragm type gauge is a very competitively price gauge/switch. Model 522 Differential Pressure Gauge & Switch is a compact and weather resistant gauge for challenging DP Applications and installations. It is suitable for use in outdoor and “Hose Down” applications. Available with our popular plug-in DIN connector switch option, both in a SPDT and SPST electrical configuration.

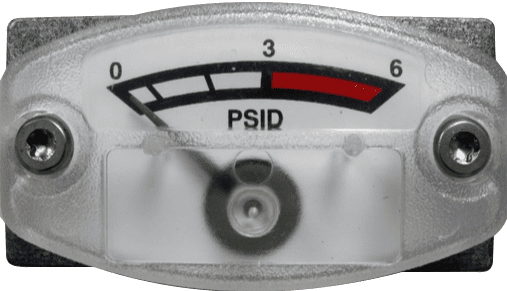

Model 522C (3-Color Dial)

Model 522 – Mid-West Instrument Tri-Color Dial (Clean/Change/Dirty) rolling diaphragm type gauge is a very competitively price gauge/switch. Available with our popular plug-in DIN connector switch option, both in a SPDT and SPST electrical option. Model 522 is available with a Full scale accuracy of ±5% (0-5 PSID to 0-50 PSID).

Model 555A (3-Color Dial)

Model 555A Diaphragm Type Differential Pressure TRI-COLOR Indicator is designed for determining the state of an in-line filter. Colored bands allow you to quickly identify pressure drop across the filter element. Divided into three sections, each is clearly marked for ease of understanding. Filtration systems require monitoring to maintain a level of performance specified by the manufacturer for the continued expectations of the end user.

Model 700 / 710 / 715

Mid-West Instrument wet/wet differential pressure transmitter utilizes a piezoresistive differential pressure sensor sensing element with stainless steel isolated diaphragm. Silicon oil is filled in between die and two diaphragms. The measured differential pressure is transmitted onto the die through the diaphragm and silicon oil. The signal output generated by the piezoresistive bridge sensor is amplified into a useable voltage or 4-20 mA output as specified by customer.

Learn More

OEM Indicators

Model 126

Model 126 – Our most affordable OEM piston type indicator with a Full scale accuracy of ±5% combined with Differential pressure range of 0-5 PSID to 0-20 PSID. Model 126 is available with clamp-on and flat pack electrical switch options. Model 126 has a lower price point while still delivering exceptional performance. Intended for use indoors or enclosed in weather protected enclosures.

Model 127

Model 127 – Our most affordable OEM piston type indicator with a Full scale accuracy of ±5% combined with Differential pressure range of 0-25 PSID to 0-100 PSID. The Model 127 is available with clamp-on and flat pack electrical switch options. The Model 127 has a lower price point while still delivering exceptional performance. Intended for use indoors or enclosed in weather protected enclosures

Learn More

Model 146

Model 146 – Our most affordable OEM diaphragm type indicator with a Full scale accuracy of ±5% combined with Differential pressure range of 0-5 PSID to 0-30 PSID. Model 146 is available with Plug-In DIN and Flat pack electrical switch options. Model 146 has a lower price point while still delivering exceptional performance.

Model 444

Model 444 – Differential Pressure Indicator offers a simple, yet functional design for use with filters, Strainers, etc…

This competitively priced indicator makes the perfect alternative to more costly Differential Pressure gauges where readability, small size and price are important considerations.

Model 522

Model 522_OEM – Mid-West Instrument rolling diaphragm type gauge is a very competitively price gauge/switch. Model 522 Differential Pressure Gauge & Switch is a compact and weather resistant gauge for challenging DP Applications and installations. Specific configurations are suitable for use in outdoor and “Hose Down” applications. Available with our popular plug-in DIN connector switch option or Flat Pack, both in a SPDT and SPST electrical option.

Model 555

Model 555 Diaphragm Type Differential Pressure TRI-COLOR Indicator is designed for determining the state of an in-line filter. Colored bands allow you to quickly identify pressure drop across element. Divided into three sections, each clearly marked for ease of understanding. Filtration systems require monitoring to maintain a level of performance specified by the manufacturer for the continued expectations of the end user.

Accessory

Model 150

The Model 150 Adjustable Pulsation Dampener and the Non-Adjustable Snubber Ball Check offers protection surge and/or pressure spikes. The 316 stainless steel ball is driven on seat by the pressure surge and held on seat as long as the differential pressure exists across the ball, while metering pressure to the instrument through a calibrated, groove across the ball seating area.

Model 200

Model 200 “Gauge Minder” features a pressure limiting valve that blocks off excess pressure to the instrument, preventing calibration failure, internal damage, and “blow-out” from over-ranging – a principal cause of instrument failure.

Test Kits

Precision Flow Test Kit 805

High accuracy portable test kit for precise flow indication and leak detection. This kit is equipped with a precise (±1% of full scale) accuracy differential pressure gauge. Popular applications include but are not limited to: measuring the pressure drop across various types of equipment i.e. filters, balancing HVAC systems, checking pump performance, orifice plates, checking calibration of transmitters, or reading flow directly when ordered with a square root dial etc.

Precision Flow Test Kit 806

High accuracy portable test kit for precise flow indication and leak detection. This kit is equipped with a precise (±1% of full scale) accuracy differential pressure gauge. Popular applications include but are not limited to: measuring the pressure drop across various types of equipment i.e. filters, balancing HVAC systems, checking pump performance, orifice plates, checking calibration of transmitters, or reading flow directly when ordered with a square root dial etc.

Precision Flow Test Kit 809

High accuracy portable test kit for precise flow indication and leak detection. This kit is equipped with a precise (±1% of full scale) accuracy differential pressure gauge. Popular applications include but are not limited to: measuring the pressure drop across various types of equipment i.e. filters, balancing HVAC systems, checking pump performance, orifice plates, checking calibration of transmitters, or reading flow directly when ordered with a square root dial etc.

Precision Flow Test Kit 820

Rugged Medium Duty Portable Test Kit. This test kit is equipped with a ±3-2-3% of full scale accuracy (ascending) piston type differential pressure gauge. Popular applications include but are not limited to, measuring pressure drop across various types of equipment, filters, checking pump performance, balancing valves, checking equipment for excessive pressure drop, leakage, etc.

Precision Flow Test Kit 831

Sensitive yet rugged medium duty portable test kit. This test kit is equipped with a ±3-2-3% of full scale accuracy (ascending) diaphragm type differential pressure gauge. Ideally suited for applications where differential pressures of 0-5” to 0-400” H2O may be encountered. Popular applications are balancing heating & cooling systems, checking pump performance, leakage, checking equipment for excessive pressure drop, (i.e. filters, balancing valves, averaging pitot tubes, orifice plates etc.) Dials may be for reading differential pressure, or reading flow directly, if ordered with a flow (square root) dial.

Precision Flow Test Kit 841

Rugged Medium Duty Portable Test Kit. This test kit is equipped with a ±3-2-3% of full scale accuracy (ascending) diaphragm type differential pressure gauge. Popular applications include but are not limited to, measuring pressure drop across various types of equipment, filters, checking pump performance, balancing valves, checking equipment for excessive pressure drop, leakage, etc.

Precision Flow Test Kit 842

Rugged (2) gauge medium duty portable flow test kit. This kit is equipped with two differential pressure gauges with complimentary dials ranges, enabling it to cover a broad range differential pressures and accuracies from ±5% to ± 3-2-3% full scale (ascending). Both gauges are protected against over-range to the maximum working pressure of the test kit. While primarily used for balancing HVAC systems it has numerous other applications which include but are not limited to: checking pump performance, checking pressure drop across filters, leakage, etc.

Precision Flow Test Kit 820

Rugged (2) gauge medium duty portable flow test kit (Models 831 & 841). This kit is equipped with two differential pressure gauges with complimentary dials ranges, enabling it to cover a broad range differential pressures and accuracies;